How Accurate is Waterjet Cutting?

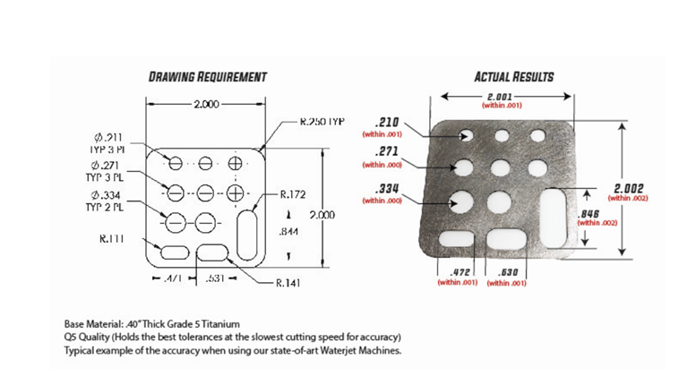

Waterjet cutting is a high precision process which can hold very tight tolerances.

The accuracy of waterjet cutting and the tolerance which can be held can vary greatly dependent on the manufacturer of the machine. This variation in accuracy is a result of the differences in technology. Waterjet cutting part tolerances typically fall between 0.003" and 0.005" of an inch and, +/-0.005" to 0.100" on thicker materials.

ICS uses state-of-the-art Flow waterjet technology which is known for having the greatest accuracy in the industry. As previously stated the accuracy varies depending on the material thickness, the chart below shows the tolerances which can be held on various thicknesses using our machines.

|

Material Thickness Range |

|

Tolerance |

||

|

.062-.250" |

.003-.005 |

|||

|

.250-.500" |

005-.007 |

|||

|

.500-1.00" |

.007-.010 |

|||

|

1.00-3.00" |

.010-.025 |

|||

|

3.00-10.00" |

|

Plan on near-net shape |

||

![ICS LOGO HQ 2020-White.png]](https://help.icscuts.com/hs-fs/hubfs/ICS%20LOGO%20HQ%202020-White.png?height=50&name=ICS%20LOGO%20HQ%202020-White.png)